Haglöfs shell guide

The outdoor industry is full of buzzwords and confusing terminology, and never more so than when it comes to shell layers. In this guide, we'll go through the fundamentals to help you confidently choose the right jacket for your next adventure.

What is a shell?

A proper shell jacket will shield you from wind and water, all while allowing moisture to escape from the body. Early shell layers fell short in breathability, making them more or less useless for physical activities. In modern shell layers, breathability is achieved through the integration of a membrane that is laminated or coated onto the back of the outer fabric.

Not all shells are made equal. Beyond waterproofness and breathability, many other factors come into play. You need to consider aspects like fit, pockets, cuffs, hems, ventilation openings, weight, packability, durability, and cost. And decide whether you’re in search of a rain jacket, an all-weather hiking jacket, specialized skiing or climbing wear, or simply an everyday go-to.

The Membrane

What defines a modern shell layer is that the fabric includes a membrane that repels water while enabling moisture to pass through. This membrane is incredibly thin, measuring between 0.03mm and 0.01mm (that’s one-tenth the width of a human hair). Thinner membranes generally offer better breathability, while thicker membranes often provide enhanced waterproofness.

The first breathable, waterproof barrier was a liquid coating, applied similar to paint, creating a flexible yet robust surface. Nowadays, most membranes are produced as separate sheets, which are then glued or bonded (laminated) onto the outer fabric.

Microporous membranes have tiny holes that allow water vapor to escape but prevent water droplets from entering. Since sweat vapor and humidity consist of small water molecules, they can pass through to the outside, while larger water droplets cannot enter.

Hydrophilic membranes draw in moisture, transferring it from the inside to the outside. The membrane absorbs sweat and then releases it on the opposite side through osmosis. Body heat accelerates the movement of moisture from inside to outside.

The Layers

The layers within a shell material should not be mistaken for the recommended layering principle of outdoor clothing (that is base, mid, and shell layers). In the context of a shell, the term “layers” refers to the number of fabrics that are fused together.

2 layers

In a 2-layer shell jacket, the membrane and outer fabric are joined to form a single material. The membrane is often shielded by a mesh material that hangs loosely on the inside. There might also be a separate lining for increased durability, and insulation between the lining and the outer shell. This is why a 2-layer jacket often ends up being bulkier and heavier compared to a 3-layer one. The additional liner also tends to give 2-layer shell jackets a softer feel. Additionally, wearing the membrane directly against the skin can hinder its performance.

2.5 layers

A 2.5-layer is a two-layer shell with an extra coating on the inside of the membrane. The “half” layer is a printed or sprayed substance on the jacket’s interior. Usually in a pattern – like dots or lines – but sometimes as a transparent coating covering the whole inner surface. The half layer serves to enhance the durability of the membrane, and provides better resistance against sweat and better next-to-skin comfort. A 2.5-layer generally reduces weight.

3 Layers

A 3-layer shell material comprises an outer fabric, a membrane, and an inner layer that protects the membrane. These three components are bonded together, creating one material. However, not all 3-layer shells are the same – there’s a wide range of technologies and materials. Some 3-layers are lightweight, breathable, and flexible, while others are sturdy and robust, designed for heavy use and extreme adventures.

The Waterproofness

Some materials are labeled “water-resistant”, meaning a tight weave that makes it tough for water to get through, but they are not suitable for extended exposure to rain. Waterproof material forms a solid barrier against water. In this guide, when we talk about shell layers, we mean waterproof shells.

Stay clear of PFAS

PFAS, aka per- and polyfluoroalkyl substances, is a group of so-called “forever chemicals” including perfluorinated compounds (PFCs) that are very effective at repelling water and fat.They have been used widely in waterproof membranes as well as durable water repellent (DWR) coatings which help maintain breathability and comfort in wet conditions by preventing the shell fabric from absorbing water, dirt, and oil. PFAS are also very long-lasting, which may be great for the longevity of a garment, but—as we now all know—not so great when it comes to the long-term consequences for the environment and human health. This is why many outdoor brands—ourselves included from FW25 onward—have decided to phase out the intentional use of these substances.

Does a PFAS-free shell = lower performance?

Most likely, you will not notice a difference. A shell that is made with a membrane and/or DWR without intentionally added PFAS will still do the job of helping you stay dry and comfortable in the rain, wind, and snow.

However, since a DWR without intentionally added PFAS is not as durable and resistant to oil and water, it may require more frequent care to maintain its water-repelling performance over the long run. This means you will need to wash and reactivate it more frequently, and reapply DWR as needed. See our care page for care tips and guidance.

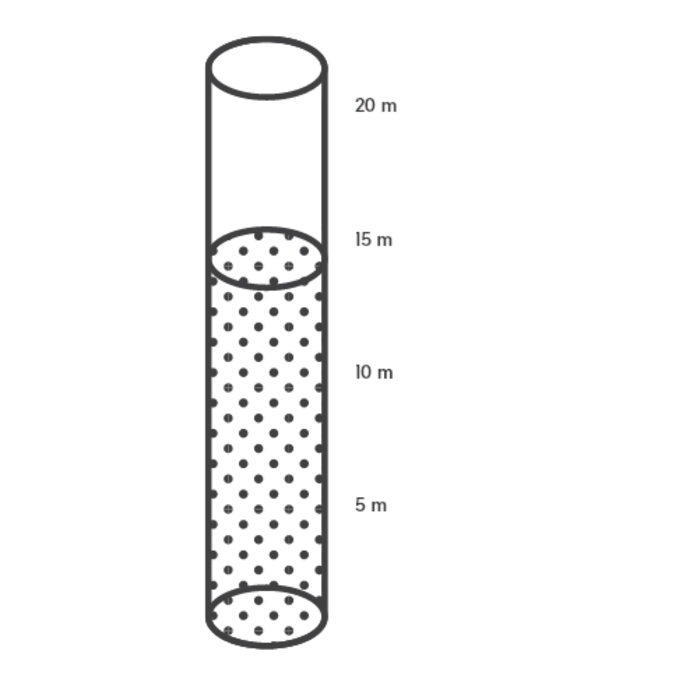

Hydrostatic head

Measuring waterproofness

The term hydrostatic head is a measure of how well a fabric can handle water pressure. Picture a water pipe covered with a shell material at the bottom end. When filling the pipe with water, it will eventually start seeping through the material at the bottom. The waterproofness is showing the height of the column of water in the pipe when water breaks through. Thus, if the water is 15 meters high in the pipe, the hydrostatic head is 15,000 mm.

— Labs don’t actually use a water pipe, but a special machine following the ISO standard. The fabric goes into this hydrostatic head machine, which gradually increases the water pressure.

How waterproof is waterproof?

Waterproof Rating (mm)

DWR – Durable Water Repellent

Most shell fabrics come with a temporary layer applied to the outside, a Durable Water Repellent – DWR. The main purpose of the DWR isn’t to shield against water, but to allow the fabric underneath to breathe. With a dry outer fabric it’s easier for the membrane to breathe out moisture. The DWR forms water into droplets that roll off the fabric instead of seeping in. Up close the DWR looks like tiny crystal hairs standing up, preventing water from reaching the surface.

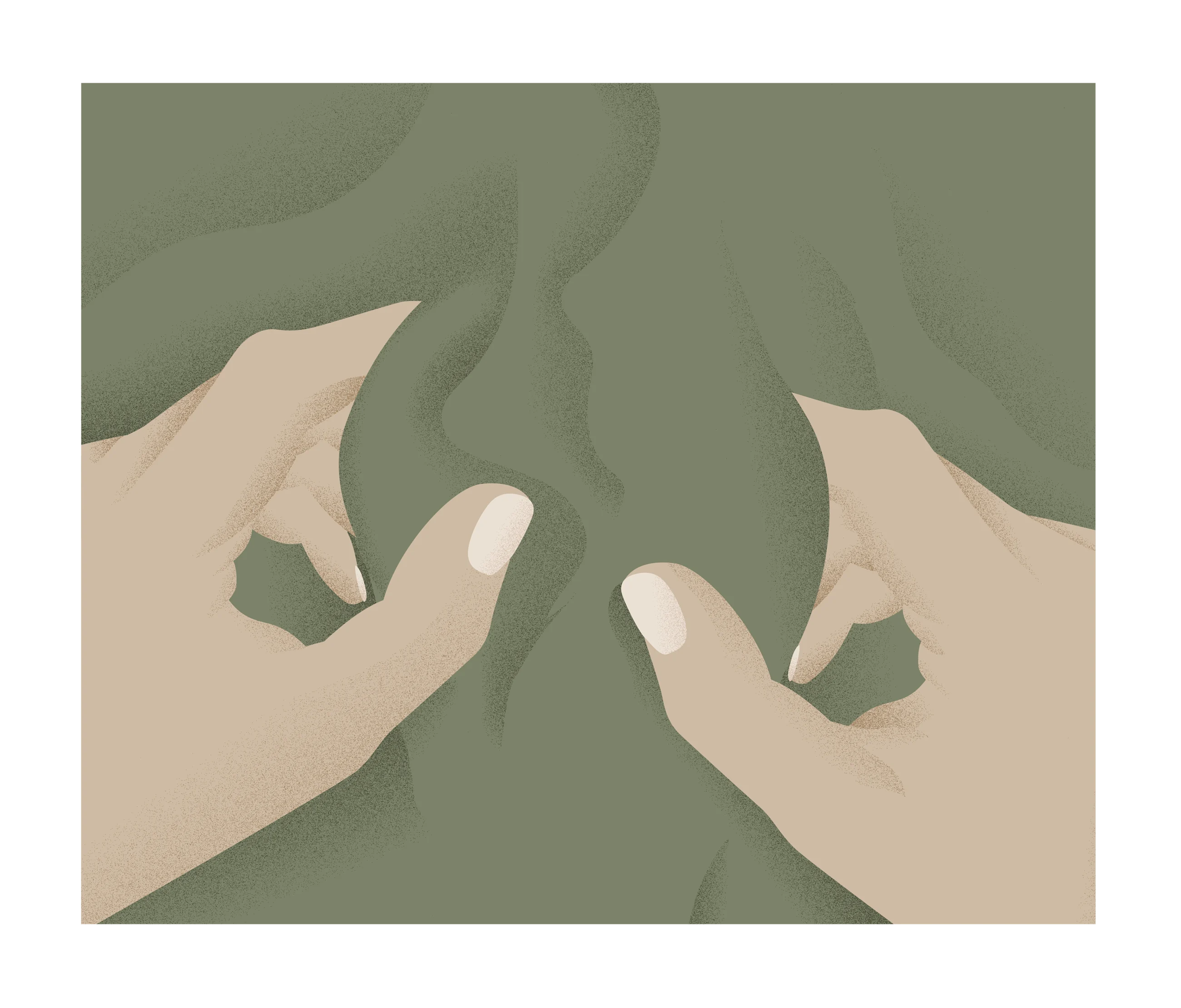

Reapplying DWR

Over time, the effect of the DWR will vanish due to wear and regular use. If you notice wet spots where the surface becomes soaked, it’s time to reapply DWR to maintain the jacket’s breathability. You can do this with either a wash-in liquid or a spray. Maximize the effectiveness of the new DWR by either warming up the garment in a drying cabinet, by using gentle tumble drying, or low-temperature ironing.

Mind the Tape

Seam taping, or seam sealing, involves applying a thin waterproof tape using heat. The tape covers the small holes created by the needle during sewing, to prevent leaks. Without effective seam sealing, even the highest quality waterproof fabric won't keep you dry. Waterproof outdoor clothing can be categorized as either “fully taped” or “critically taped”. In a fully taped garment, every seam is covered with tape, whereas a critically taped one only has tape on high-exposure zones like the neck, shoulders, and chest.

Breathability

What is breathability?

Even during light activity, our bodies release sweat and humidity. In non-breathable gear, moisture is trapped inside your jacket. This makes it clammy, and when temperatures drop it can quickly turn chilly and even lead to hypothermia.

A shell’s “breathability” is its ability to let moisture escape from the inside through its membrane – essential to keep you dry and comfortable. Differential pressure maintained by your body heat drives vapor from the warm, moist interior to the chillier and drier exterior. There is a number of different methods to measure fabric breathability.

Measuring breathability

Resistance of Evaporation of a Textile (RET)

Even during light activity, our bodies release sweat and humidity. In non-breathable gear, moisture is trapped inside your jacket. This makes it clammy, and when temperatures drop it can quickly turn chilly and even lead to hypothermia.

A shell’s “breathability” is its ability to let moisture escape from the inside through its membrane – essential to keep you dry and comfortable. Differential pressure maintained by your body heat drives vapor from the warm, moist interior to the chillier and drier exterior. There is a number of different methods to measure fabric breathability.

RET Comfort Rating

Moisture Vapor Transmission (MVT)

In “The Inverted Cup Test” the fabric is wrapped over a cup filled with a desiccant, which is then placed upside down in a pan of water. After a set time, the cup is weighed to see how much water has been pulled through the fabric – the cup’s weight shows the MVT Rate (MVTR) measured in grams per m2 per day.

Does more breathability always mean better comfort?

Comfort can come from many elements, including the breathability, weight and stretch of the fabric. We measure how breathable a fabric is, but there are other properties that impact the comfort, so always consider the overall design and use. Some jackets feature extra ventilation, like armpit zippers or a fast-wicking lining.

Remember:

Lower RET-value =

Higher MVTR-value =

Better breathability

The Materials

GORE-TEX

The GORE-TEX brand, founded by the American manufacturer W.L. Gore and associates, has been spearheading innovation in the shell-layer industry for years with a number of groundbreaking technologies. They offer a wide range of durably waterproof materials used for shell layers such as GORE-TEX®, GORE-TEX ePE, GORE-TEX Paclite®, GORE-TEX Active®, and GORE-TEX Pro® – all with their respective benefits and strengths.

PROOF™

PROOF™ is Haglöfs’ own waterproof technology and consists of a handpicked selection of materials. The PROOF™ product range utilizes 2-layer, 2.5-layer, and 3-layer shell fabrics to suit diverse activities and conditions. PROOF™ materials are recycled, bluesign® approved, and always free from intentionally added PFAS, meaning that they comply with the gold standard of sustainability within the textile industry.

Durability and Care

There are a number of factors that can impact the durability of a shell fabric:

The denier and weight of the face fabric used

The method of the face fabric construction (e.g. woven or knitted)

The type of material and fabrics used

The type of membranes used. (e.g. PES, PU, ePE or ePTFE)

Wash your shell to maintain its function

To keep your shell jacket working its best, regular maintenance is needed. Accumulated dirt clogs the pores in the membrane, making the jacket less breathable. If your shell jacket (or pant) gets dirty, or when the outer layer gets damp from light rain, it’s time for a wash and reproofing. Washing not only cleans the garment but also maintains its waterproofing and breathability.

1. Wash

Follow the washing instructions on the care label inside the garment. Always close zippers and any Velcro straps before washing. Do not use fabric softener. If no instructions can be found, machine wash at 40°C, mild process. Do not bleach or dry clean.

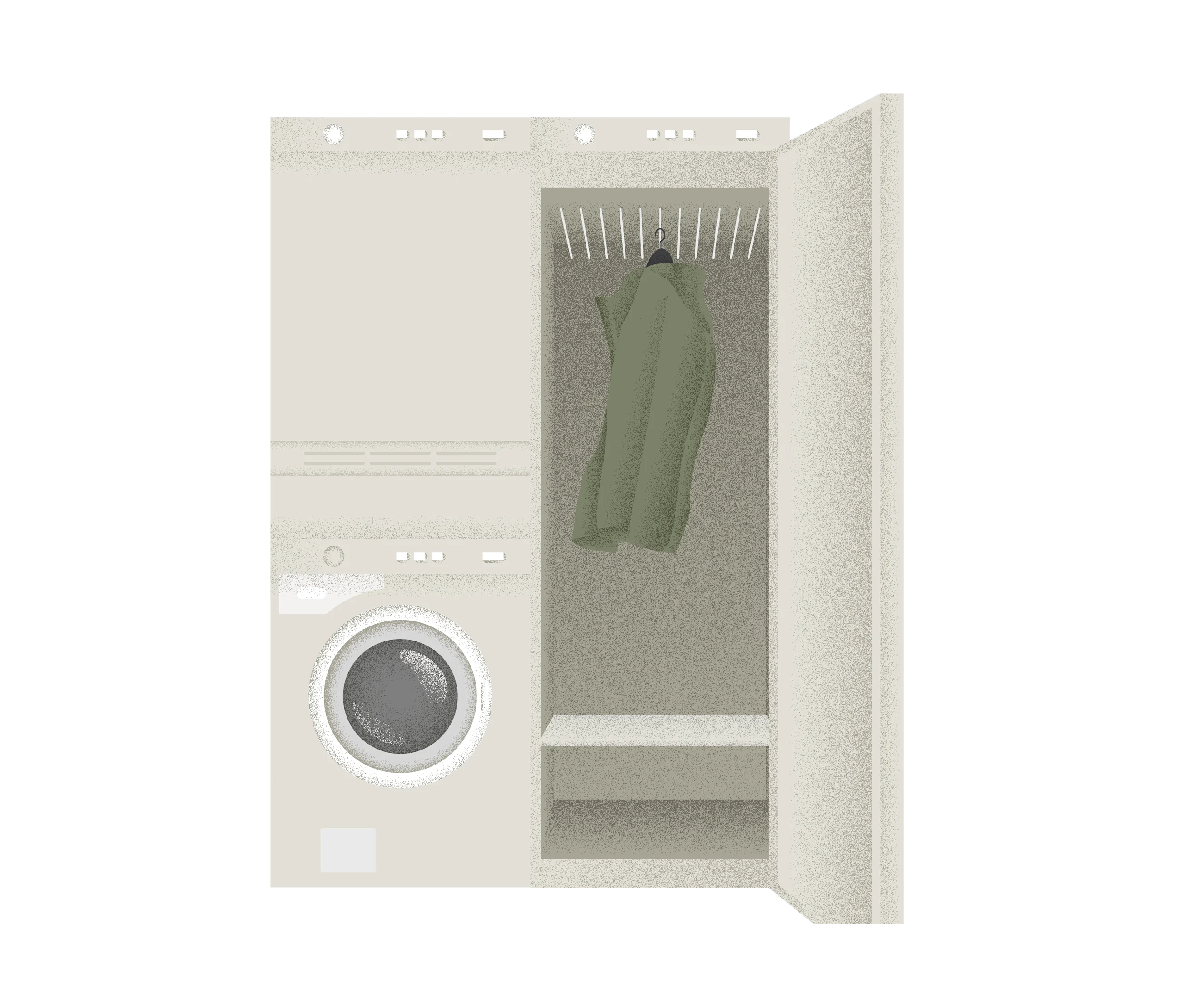

2. Dry

Adding heat during drying reactivates the DWR treatment on the fabric surface. Preferably in a drying cabinet or by ironing the garment on low heat, as tumble dryers may cause greater wear. Drip drying your garment without the addition of heat may impair its water-repelling qualities.

3. Reapply DWR when needed

Reimpregnate the entire garment, or exposed areas, if the outer surface becomes soaked by water already in light rain. Use a DWR product suitable for breathable garments and follow the instructions on the packaging.